1. Scope of Asme Standard Bolts

1.1 This specification covers alloy and steel bolting for stress valves and valves, and flanges, and fittings to get higher Temperature or higher pressure assistance, or alternative special intent applications. Watch Specification A962/A962M for your Meaning of bolting. Bars and cable will probably be hot-wrought and Might function as further processed with centreless grinding or from a cool drawing. Austenitic steel could Be carbide alternative handled or Carbide remedy medicated and strain-hardened. When pressure engineered austenitic steel has been arranged, the buyer needs to simply take special attention to be certain Appendix X1 is extensively known.

1.2 Several grades are covered, such as ferritic steels and also austenitic stainless steels specified B5, B8, and thus on. Selection depends on service, design requirements, mechanical attributes, and also higher temperature features.

1.3 The subsequent referenced overall demands are crucial for use of the Resource: Specification A962/A962M.

NOTE 1-The committee inventing this specification contains comprised several steel kinds which have now been quite broadly employed for its current purpose. Additional compositions will probably be considered for addition from the committee every once in a while the demand gets clear.

NOTE 2-For grades of alloy Asme standard steel bolting appropriate to be used in the reduced array of higher temperatures applications, mention needs to be designed to Specification A354.

Note 3-For grades of alloy steel bolting appropriate to be used at non-temperature applications, mention ought to be created to interrogate.

A320/A320M.

1.4 Supplementary prerequisites are supplied for use in an alternative of the buyer. The supplemental demands will Apply just once defined from the buy contract or order.

1.5 This specification is extracted in equally inch-pound Models As well as in SI components nonetheless unless of course the buy contract or order Defines the related M specification designation (SI units), That the inch-pound models will employ.

1.6 The values stated in SI units or inch-pound Models must be considered separately as ordinary. Inside of the text, then that the SI models are displayed in mounts. The values mentioned in every system might not be accurate equivalents; hence, just about every technique may be properly used independently of one opposite. Combining worth from both systems may come in non-conformance with all the standards.

2.General Conditions and Buying Information

2.1 The question and requests will Incorporate the next, as mandatory, to clarify exactly the desirable material satisfactorily:

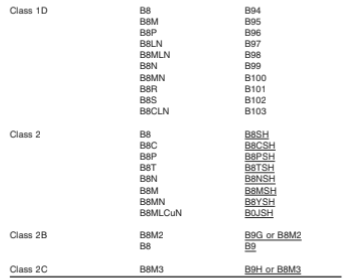

2.1.1 Heat-treated Ailment (that’s carbide solution treated (Class 1 ), carbide remedy handled following completing (Class 1A), and also carbide remedy medicated and strain-hardened (Class 2, 2B and 2C ), such as its austenitic stainless steels; Courses 1B and also 1C apply into this carbide solution-treated nitrogen-bearing stainless steels; course 1D pertains to substance carbide remedy took care of by cooling immediately from your rolling temperatures ),

2.1.2 Description of things demanded (that’s, bars, bolts, screws or studs),

2.1.3 Nuts, should need by the buyer, according to 12.1.

2.1.4 Supplementary needs, if any other, also

2.1.5 Particular conditions, according to 5.1, 5.2.6, 7.1, also 12.1.

2.2 Coatings-Coatings are prohibited unless given by the buyer (Watch Supplementary Prerequisites S12 and S13). When coated attachments are all arranged the buyer ought to choose Special attention to be certain Appendix x-2 is entirely known.

3.Typical Requirements

3.1 Bolting provided for the specification will adapt to that the demands of Specification A962/A962M. All these requirements comprise evaluation test methods, finish, thread dimensions, macroetch (alloy steels only), signalling, certificate, optional supplementary conditions, along with also others. Struggling to honor with certain needs of Specification A962/A962M comprises non-conformance for this specific specification. In case of conflict between this specification and Specification A962/A962M, this specification shall prevail.

4.Manufacture (Process)

4.1 The Metal will likely be generated with some of those next Procedures: Open-hearth, basic-oxygen, electric-furnace, or vacuum-induction melting (VIM). Molten steel Could Be Vacuum-treated ahead of during the pouring of this ingot or even strand casting.

4.2 Good Quality –Watch A962/A962M on demands.

5.Heat-treatment

5.1 Ferritic Steels

5.1.1 Ferritic steels will likely be permitted to cool for some temperature beneath the cooling range instantly afterward rolling or hammering. Materials will subsequently be re-heated to the appropriate fever to enhance the grain (a set so re-heated being understood like a quenching fee), quenched at a Liquid moderate under appreciably uniform states such as just about every quenching fee, and also hardened. The minimal tempering temperature will be specified in Tables 3 and 2.

5.1.2 Utilization of water quenching is not allowed for practically any ferritic grade when heating therapy is completed later threading or heading.

5.1.3 Other than as allowed underneath for B6X; materials that are cold attracted for the dimensional controller will likely be stress-relieved right after cold drawing. The minimal stress-relief temperatures will be 100 °F [55 °C] beneath the tempering temperature. Exams for mechanical houses will likely be carried out right after stress relieving.

5.1.4 B6 and also B6X will likely be kept in the tempering temperatures for at a time period of just 1 h. B6X substance could be supplied from the as-rolled-and-tempered ailment. Cold-working after heating therapy is allowed for B6X substance given the last hardness suits certain prerequisites of Tables 3 and 2.

5.1.5 B7 and also B7M will likely be heat handled with quenching at a liquid moderate and tempering. To get B7M attachments, the last heat therapy, which may function as the tempering surgery should run in 1150 °F [620 °C] minimal, will be achieved all things considered machining and forming procedures, for example, thread rolling and some other form of cuttings. Surface prep for hardness testing, non-destructive test, or ultrasonic bolt tensioning is allowed.

5.1.5.1 Until otherwise specified, material for Grade B7 could be heating cured with the Furnace, the Induction, or the Electric Resistance method.

NOTE 4-Stress-relaxation possessions might differ from warmth to heating or those properties can change from 1 heat-treating way to the next. The buyer may define Supplementary Necessity S8 when stress relaxation analysis is wanted.

5.1.6 Material Grade B16 will be warmed to a temperature range from 1700 to 1750 °F [925 to 955 °C] and oil extinguished. The base hardening temperature will be as determined in Tables 2 and 3.

5.2 Austenitic Stainless Steels

5.2.1 All austenitic hardened steels will get a carbide arrangement treatment (see 6.2.2-6.2.5 for explicit prerequisites for each class). Classes, 1, 1B, 1C (Just grades B8R and B8S), 2, 2B, and 2C can apply to bar, wire, and completed fasteners. Class 1A (all evaluations) and Class 1C (Just grades B8RA and B8SA) can apply to complete fasteners. Class 1D applies just to bar also, wire, and completed fasteners that are machined straightforwardly from Class 1D bar or wire with no resulting hot or cold working.

5.2.2 Classes 1 and 1B, and Class 1C Grades B8R and B8S—After moving of the bar, forging, or heading, regardless of whether done hot or cold, the material will be warmed from surrounding temperature and held an adequate time at a temperature at which the chromium carbide will go into an arrangement and afterward will be cooled at a rate adequate to forestall the precipitation of the carbide.

5.2.3 Class 1D—Rolled or forged Grades B8, B8M, B8P, B8LN, B8MLN, B8N, B8MN, B8R, and B8S bar will be cooled quickly promptly following hot working while the temperature is over 1750 °F [955 °C] so that grain limit carbides stay in the solution. Class 1D will be limited to applications at temperatures under 850 °F [455 °C].

5.2.4 Class 1A and Class 1C Grades B8RA and B8SA— Completed fasteners will be carbide arrangement treated all things considered rolling, forging, heading, and threading tasks are finished. This designation doesn’t make a difference to beginning material such as a bar. Fasteners will be warmed from encompassing temperature and held an adequate time at a temperature at which the chromium carbide will go into the arrangement and afterward will be cooled at a rate adequate to forestall the precipitation of the carbide.

5.2.5 Classes 2, 2B, and 2C—Material will be carbide arrangement treated by warming from surrounding temperature and holding an adequate time at a temperature at which the chromium carbide will go into an arrangement and afterward cooling at a rate adequate to forestall the precipitation of the carbide. Following this treatment, the material will at that point be a strain solidified to accomplish the necessary properties.

NOTE 5—Heat treatment following activities performed on a restricted part of the item, for example, heading, may bring about non-uniform grain size and mechanical properties through the segment influenced.

5.2.6 If a without scale splendid completion is required; this will be indicated in the buy request.

6. Compound Composition

6.1 Each alloy will adjust to the substance creation necessities endorsed in Table 1.

7. Heat Analysis

7.1 An analysis of every heat of steel will likely be drawn up from the manufacturer to fix the proportions of these elements given in section 7. The chemical compound makeup consequently ascertained will be noted on the buyer or the buyer’s Representative, and will comply with certain requirements given In Section 7. In case the buyer possesses It Essential to possess the changeover zone of 2 heats sequentially throw lost, the buyer shall invoke Supplementary prerequisite S3 of specification A788/A788M.

8. Mechanical Properties

8.1 Tensile Houses:

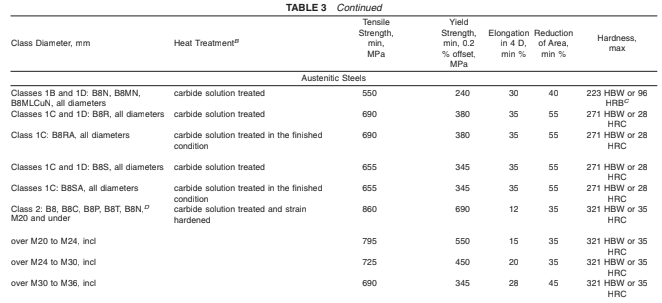

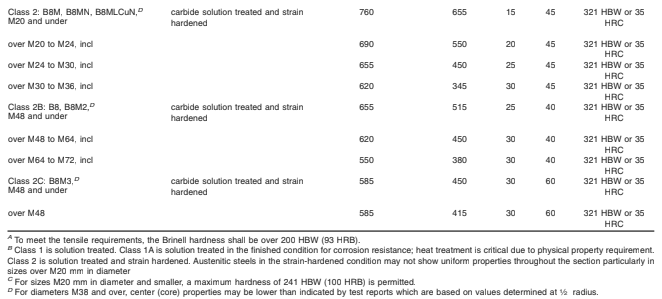

8.1.1 Conditions -The substance as signified with the stress specimens will adapt to certain requirements in Tables 3 and 2 at room temperature immediately after the heating treatment method. Instead, stainless pressure tempered fasteners (Course 2, 2B, and 2C) will likely be analyzed full Dimensions following anxiety Hardening to find out tensile strength and yield power and shall adapt to certain requirements in Tables 3 and 2.In case the outcomes of full Measurement evaluations battle using outcomes of stress specimen evaluations, full dimensions evaluation results will predominate.

8.1.2 Full Measurement Fasteners, Wedge Tensile Screening -After Associated, visit 12.1.3, head fasteners will likely be tested fully measurement. The Minimal full measurement load implemented (lbf or kN) to get Individual sizes will function the following:

W=T, XA,

Exactly where:

W = minimum wedge tensile load without even break,

Ts = tensile strength defined in ksi or MPa at Tables 2 and also 3, also

At = stress Region of the thread segment, square inches or square millimeters, as exhibited at the cone evidence Load tables in specification A962/A962M.

8.2 Hardness Requirements:

8.2.1 The hardness will adapt to certain requirements in Tables 3 and 2. Hardness testing will be done according to Specification A962/A962M or using evaluation strategies F606.

8.2.2 Grade B7M-The highest hardness of this grade may be 235 HBW or even 93 HRB. The minimal hardness will Less than 200 HBW or even 93 HRB. Conformance for the Hardness will likely be guaranteed by analyzing the hardness of about every stud or bolt from Brinell or Rockwell B techniques according to 8.2.1. The usage of 100% electromagnetic screening for hardness because an alternate to 100 percent indentation hardness screening is permissible when characterized by simply sampling utilizing indentation hardness testing. Each ton analyzed for hardness electromagnetically will be 100% analyzed because of Exercise E566. After electromagnetic screening for hardness per 100 samples of some the last 100 bits of every heating of metal in just about every good deal (because defined in 11.1.1) will likely be analyzed by indentation hardness techniques. All trials have to fulfill hardness prerequisites. Enable approval of this great deal. If any 1 sample is still out of this predetermined minimum or maximum hardness, the bulk will soon be refused and reprocessed and resampled or analyzed 100 percent by indentation hardness procedures.

8.2.2.1 Area preparation for indentation hardness Screening Shall be in agreement with evaluation strategies E18. Hardness evaluations will likely be done at the close of the stud or bolt. If that really is Impractical, the hardness evaluation will be carried out elsewhere.

9. Workmanship, Finish, and Appearance

9.1 ASME Standard Bolts, screws, studs, and stud bolts shall be pointed and will possess a workmanlike complete. Points shall be horizontal and chamfered or rounded in the alternative of this producer. Length of a point on stud and studs bolts shall be less than one nor more than two whole threads measured from the end parallel to your axis. Length of stud and studs bolts shall be measured from first thread to original thread.

9.2 Except otherwise given at the Buy order, bolt heads will be following all the measurements of ASME standard B18.2.1 or ASME standard B18.2.3.3M. Unless differently specified at the purchase order, the Heavy Hex Screws Series ought to be used for nominal body diameters of 11⁄4 at [30 mm] rather much less. To get in larger dimensions, the weighty Hex Screw Series should really be properly used, except the maximum body diameter and radius for the weighty Hex cap screws of fillet may be the same as for the weighty Hex head Bolt Series. The body diameter and radius for sizes of Heavy Hex cap Screws and bolts that are not displayed within their various tables at ASME standard B18.2.1Or ASME standard B18.2.3.3M could be shown at the corresponding Hex Cap Screw and bolt tables respectively. Socket head fasteners will be based on ASME standard B18.3 or ASME standard B18.3.1M.

10. Re-tests

10.1 If the test of the mechanical evaluations of any test majority doesn’t conform to certain requirements specified, the manufacturer may retreat this lot perhaps more than double, at which the event two additional stress evaluations shall be made from this type, all of which shall conform to certain requirements specified.

11. Evaluation Specimens

11.1 Quantity of tests for heat-treated bars, 1 tension evaluation will likely be created for every single diameter of every single heating symbolized in each tempering fee. When heating handled with no disturbance in constant furnaces, the material at a lot will likely be precisely the same warmth, the same former state the exact equal dimensions, and also exposed to this same warmth therapy. Much Less than just two stress evaluations are required for every lot comprising 20 000 1b [9000 kg] or even less. Every Extra 10 000 1b [4500 Kilogram] or percent thereof requires one extra evaluation.

11.1.1 for studs, screws, bolts, Etc., 1 pressure test shall be made for just about every diameter of every heat entailed with the whole lot. Every lot will include these next:

Diameter, in. [mm] Lot Size

11⁄8 [30] and under 1500 lb [780 kg] or fraction thereof

Over 11⁄8 [30] to 13⁄4 [42], incl 4500 lb [2000 kg] or fraction thereof

Over 13⁄4 [42] to 21⁄2 [64], incl 6000 lb [2700 kg] or fraction thereof

Over 21⁄2 [64] 100 pieces or fraction thereof

11.1.2 Pressure evaluations Aren’t needed to be produced on bolts, screws, or stud bolts that are fabricated from heat-treated bars supplied given certain requirements with the specification and analyzed according to 11.1, given that they are not granted another heating therapy.

11.1.3 Full-Size Specimens, Headed Fasteners—Headed fasteners 11⁄2 in. in body diameter and smaller, with body length three times the diameter longer, and then which are created by upsetting or forging (cold or hot ) will likely be exposed to full Size analysis according to 8.1.2. This testing will maintain addition to tensile screening as stated in 8.1.1. Wedge tensile testing will likely be restricted by-product or service with socket head caps screw, even the lot dimensions will likely be shown in 11.1.1. Failure will happen in the body or threaded section with no failure, or signs of failure, like cracks, in the intersection of their head and shank. Wedge tensile Screening isn’t necessary for the horizontal countersunk head or socket button products.

12. Nuts

12.1 Bolts, studs, and also stud bolts will be supplied with nuts, even when defined from the buy order. Nuts shall adapt to specification A194/A194M.

13. Certification

13.1 Certification is demanded. Along with the specific Needs of Specification A962/A962M, the accounts will comprise the consequences of this chemical investigation, macroetch evaluation (Carbon and Alloy Steels Only), along with mechanical evaluations, and also say that the approach to heating treatment utilized.

14. Product Marking

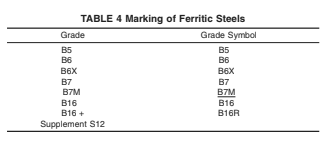

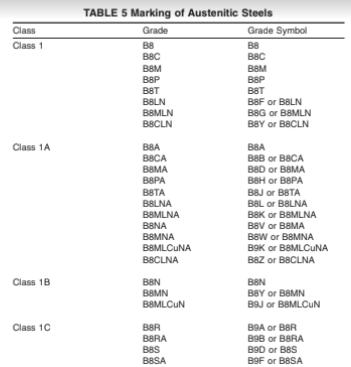

14.1 See Specification A962/A962M. The grade symbol may be shown in Table 4 and Table 5. Grade B7M will soon be 100% assessed from conformance with all the specifications along with will possess a line up below the grade symbol.

15. Keywords

15.1 alloy steel bars; alloy steel bolting; fasteners; hardness; heat therapy; stainless steel bolting

SUPPLEMENTARY Demands

These demands will not use unless defined from the Purchase and at the Buying Facts, in that event that the given tests will likely be produced before dispatch of the goods.

S1. High-Temperature Tests

S-1.1 Test to ascertain high-temperature possessions will be created given exam strategies E21, E139, along with E292, and techniques E150 and also E151.

S2. Charpy Impact Exams

S2.1 Charpy impact evaluations depending on the needs of Specification A320/A320M, Sections 7 and 6, will be produced as agreed between the manufacturer and the buyer. When testing temperatures are as little as the ones given in Specification A320/A320M, bolting ought to be arranged compared to this specification in taste with the specification.

S3. 100 % Hardness evaluation of Grade B7M

S3.1 Every Grade B7M stud or ASME standard bolt will probably be analyzed to get hardness by indentation procedure and will satisfy certain requirements given in Tables 3 and 2.

S4. Hardness testing of grade B16

S4.1 For studs or bolts 21⁄2 in. [65mm ] or smaller, the more hardness for Grade B16 will likely be quantified on or close to the finish Of every stud or bolt with a few of those processes recommended in 8.2.1 for your Brinell or Rockwell C evaluation. The hardness will be in the scope 253-319 HBW or even 25-34 HRC.

S5. Product Marking

S5.1 Grade and manufacturer’s identification logos will be put on an ending of studs and also into the heads of both bolts of most sizes. (When the accessible place is insufficient, then the grade symbols can be indicated at a single side of the end and also the manufacturer’s identification symbol marked about the opposite finish.) For ASME standard bolts smaller than 1⁄4 in. [6 mm] in studs and diameter smaller compared to 3⁄8 in. [10 mm] in diameter and also for 1⁄4 in. [6 mm] in diameter required significantly more than just a total of 3 symbols, the marking will likely be a matter of arrangement between the buyer and the manufacturer.

S6. Stress-relieving

S6.1 a stress-relieving operation will follow straightening after heating therapy.

S6.2 the minimal stress-relieving temperatures will be 100 °F [55 °C] below the tempering temperature. Tests for mechanical properties will likely be carried out right after stress-relieving.

S7. Magnetic Particle Inspection

S7.1 Bar will likely be magnetic particle analyzed according to guide E709. Bars with signs of cracks or seams are at the subject of rejection in the event the induction stretch more than 3% of this diameter in the bar.

S8. Stress-Relaxation Testing

S8.1 Stress-Relaxation Testing, if demanded, will be accomplished in line with exam strategies E328. The evaluation will be completed at 850 °F [454 °C] to get a time of a hundred h. The first stress will likely be fifty M psi [345 MPa]. The remainder pressure in 100 h shall be 17 Mpsi [117 MPa] minimum.

S9. Grain Dimension Prerequisites for non-H Grade Austenitic Steels Utilized Above 1,000 °F

S-9.1 For design alloy temperatures above a 1,000 °F [540°C], the material will probably have grain dimensions of No. 7 or even coarser as established given evaluation strategies E112. The grain size so decided will be mentioned to the Certification of evaluation.

S10. Hardness Screening of Class two bolting to get ASME standard applications

S10.1 The maximum hardness will be Rockwell C35 instantaneously underneath the thread roots. The hardness will be taken. On a horizontal place in 1⁄8 in. [3 mm] around, ready by removing threads, no longer material than mandatory will probably be removed to get ready the exact horizontal locations. Hardness determinations will likely be drawn up at the same frequency as tensile evaluations.

S 11. Thread Forming

S 11.1 Threads will likely be shaped right after heating treatment. Application of the supplementary necessity to grade B7M or also the grades recorded in 6.2.4 is not allowed.

S 12.Stress rupture testing of grade B16

S 12.1 one particular evaluation will likely be designed for just about every heat treat lot. Testing shall be executed with a combo evaluation pub according to evaluation techniques E292. Rupture shall happen in the smooth section of every test. The evaluation will probably 1100 °F [595 °C] and 20 ksi [140 MPa]. The evaluation will last before the sample ruptures. Rupture life will likely be 25 h minimal. Testing isn’t mandatory on material significantly less than 1⁄2 in. [12 mm] thick.

S 12.2 after a Buy arrangement for fasteners invokes S12, the grade emblem applied will likely be”B16R.”

S13. Coatings on Fasteners

S13.1 it’s the buyer’s duty to define from the order buy all info expected from the coated center. Examples of this advice might comprise but aren’t restricted into the subsequent:

S13.1.1 Reference to the Proper layer specification and sort, thickness, place, alteration to size, and hydrogen embrittlement reduction.

S13.1.2 Mention of the Specifications A153/A153M, B633, B695, B696, B766, or F1941, F2329, or test method F1940, or other standards.

S14. Marking Coating Fasteners

S14.1 Material coated with zinc will have ZN marked following the grade symbol. Material coated with cadmium shall have CD marked following the grade symbol.

NOTE S14.1—as an example, the marking for zinc-coated B7 will now be B7ZN rather than B7.